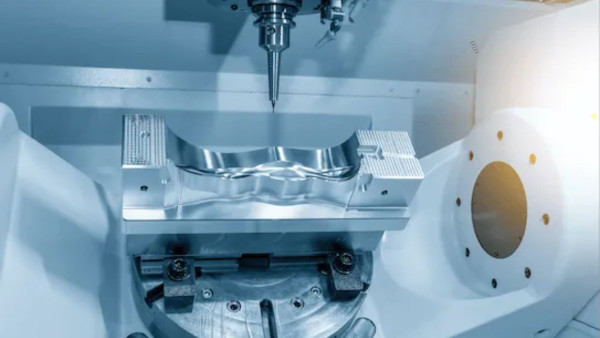

United States, 27th May 2024 – Kemal Precision Manufacturing is pleased to announce the launch of its state-of-the-art CNC machining services online, offering unparalleled quality and precision to meet the diverse needs of various industries kemalmfg.com/cnc-machining/services/. This new service aims to deliver high-quality parts with extreme accuracy, ensuring timely delivery and exceeding client expectations.

Kemal Precision Manufacturing, a leader in precision machining, is known for its advanced technology and commitment to excellence. The company’s on-demand CNC machining services are designed to provide clients with reliable and efficient solutions for their manufacturing needs. Using sensors and data to adjust cutting parameters in real time, Kemal ensures that each part produced meets the highest standards of precision and quality.

“Introducing the CNC machining services is a significant advancement for Kemal Precision Manufacturing,” said Jason Lee, CEO of Kemal Precision Manufacturing. “The goal is to provide clients with top-tier machining solutions that deliver exceptional precision and reliability. This service exemplifies the dedication to using cutting-edge technology to meet and exceed client expectations.”

Kemal’s CNC machining services online cater to a wide range of applications, including the production of axial and radial holes, flats, grooves, slots, and other cylindrical features. The company’s expertise in CNC machining allows it to handle complex projects with ease, ensuring that every part is manufactured to exact specifications. Depending on the scope of the order and the processes chosen, clients can receive their parts in as little as five days.

The company’s commitment to quality is evident in its use of advanced technology and stringent quality control processes. Kemal’s CNC machining services are backed by industry-leading certifications, ensuring that clients receive parts that meet the highest standards of performance and durability. This dedication to quality has earned Kemal a reputation as a trusted partner in the manufacturing industry.

Looking to the future, Kemal Precision Manufacturing is committed to continuous innovation and improvement. “The vision is to remain at the forefront of the CNC machining industry, continually enhancing the capabilities and exploring new technologies,” added Lee. “The team is dedicated to expanding the services and providing clients with the most advanced and reliable machining solutions available.”

Kemal’s CNC machining services are designed to meet the needs of various industries, including automotive, aerospace, medical devices, and consumer electronics. The ability to produce high-precision parts quickly and efficiently allows companies in these sectors to maintain a competitive edge and bring their products to market faster.

The launch of these services underscores Kemal Precision Manufacturing’s commitment to providing innovative solutions that drive efficiency and quality in manufacturing. By offering a complete suite of CNC machining services online, the company aims to support its clients’ efforts to achieve their manufacturing goals with precision and reliability.

Kemal Precision Manufacturing is dedicated to helping clients achieve their manufacturing objectives with expert guidance and cutting-edge technology. For more information about Kemal Precision Manufacturing’s CNC machining services, those interested can contact the company at +1 770-365-0810 or email km@kemalmfg.com.

Media Contact

Organization: Kemal Precision Manufacturing

Contact Person: Jason Lee

Website: https://www.kemalmfg.com/

Email: km@kemalmfg.com

Contact Number: +17703650810

Country: United States

Release Id: 27052412516

The post Kemal Precision Manufacturing Announces CNC Machining Services appeared first on King NewsWire. It is provided by a third-party content provider. King Newswire makes no warranties or representations in connection with it.

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No FUNDS MANAGEMENT journalist was involved in the writing and production of this article.